Over the years, technology has allowed a variety of options for industrial printing. Two of the most common are offset and digital printing. Offset more traditional forms and has been used for well over one hundred years. On the other hand, the development of digital printing offers new solutions to the industry. Both options have benefits and setbacks. Learn below what you should know when you’re choosing between offset and digital printing.

Offset Printing

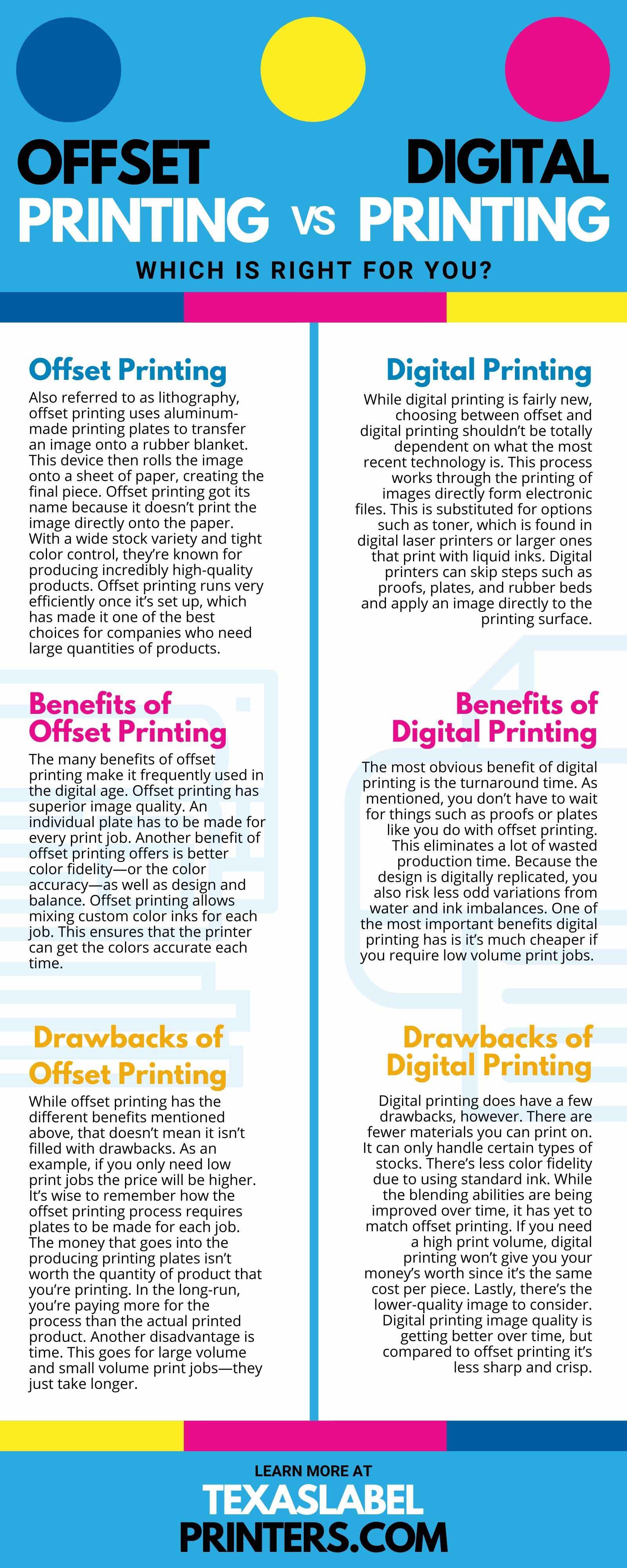

Also referred to as lithography, offset printing uses aluminum-made printing plates to transfer an image onto a rubber blanket. This device then rolls the image onto a sheet of paper, creating the final piece. Offset printing got its name because it doesn’t print the image directly onto the paper. With a wide stock variety and tight color control, they’re known for producing incredibly high-quality products. Offset printing runs very efficiently once it’s set up, which has made it one of the best choices for companies who need large quantities of products. For this reason, many companies that require large amounts of labels often choose offset printing.

Benefits of Offset Printing

The many benefits of offset printing make it frequently used in the digital age. Offset printing has superior image quality. An individual plate has to be made for every print job. Another benefit of offset printing offers is better color fidelity—or the color accuracy—as well as design and balance. Offset printing allows mixing custom color inks for each job. This ensures that the printer can get the colors accurate each time. You can also get the same print quality on any material. This is especially helpful for product labels that require being made of different stocks. Lastly, you’ll get a quality product for your money if you require large volume print jobs. After the plates are made and materials ready, the cost is less than digital printing for a large volume job. And, it’s the same price per piece no matter the job size.

Drawbacks of Offset Printing

While offset printing has the different benefits mentioned above, that doesn’t mean it isn’t filled with drawbacks. As an example, if you only need low print jobs the price will be higher. It’s wise to remember how the offset printing process requires plates to be made for each job. The money that goes into the producing printing plates isn’t worth the quantity of product that you’re printing. In the long-run, you’re paying more for the process than the actual printed product. Another disadvantage is time. This goes for large volume and small volume print jobs—they just take longer. It takes time to create every individual printing plate. If you need an emergency batch of labels made quickly, offset printing will only set you back. This connects to the last drawback: the fallout of mistakes in image design. If there’s an error and a whole batch is ruined, it’s far harder to fix. The process will have to be started all over again, including the making of the plate. More money and time will be wasted.

Digital Printing

While digital printing is fairly new, choosing between offset and digital printing shouldn’t be totally dependent on what the most recent technology is. This process works through the printing of images directly form electronic files. This is substituted for options such as toner, which is found in digital laser printers or larger ones that print with liquid inks. Digital printers can skip steps such as proofs, plates, and rubber beds and apply an image directly to the printing surface. Large digital printers work the same way as at-home inkjet and laser-jet printers, except they’re bigger, faster, and more precise. Their print quality is be better and more consistent than a home-printed product.

Benefits of Digital Printing

The most obvious benefit of digital printing is the turnaround time. As mentioned, you don’t have to wait for things such as proofs or plates like you do with offset printing. This eliminates a lot of wasted production time. Because the design is digitally replicated, you also risk less odd variations from water and ink imbalances. One of the most important benefits digital printing has is it’s much cheaper if you require low volume print jobs. You don’t have to worry about the expense of creating a plate. If you have an error in the design, this is also much easier to fix with digital printing. You can halt the batch, go in and fix what needs to be changed, and send to new file to the printer with hardly any time and money wasted.

Drawbacks of Digital Printing

Digital printing does have a few drawbacks, however. There are fewer materials you can print on. It can only handle certain types of stocks. There’s less color fidelity due to using standard ink. While the blending abilities are being improved over time, it has yet to match offset printing. If you need a high print volume, digital printing won’t give you your money’s worth since it’s the same cost per piece. Lastly, there’s the lower-quality image to consider. Digital printing image quality is getting better over time, but compared to offset printing it’s less sharp and crisp.

Texas Label Printers offers a great selection of printing equipment such as the continuous roll label printer, and other digital designs. Here you’ll find industrial label printers from the industry’s highest-quality brands.