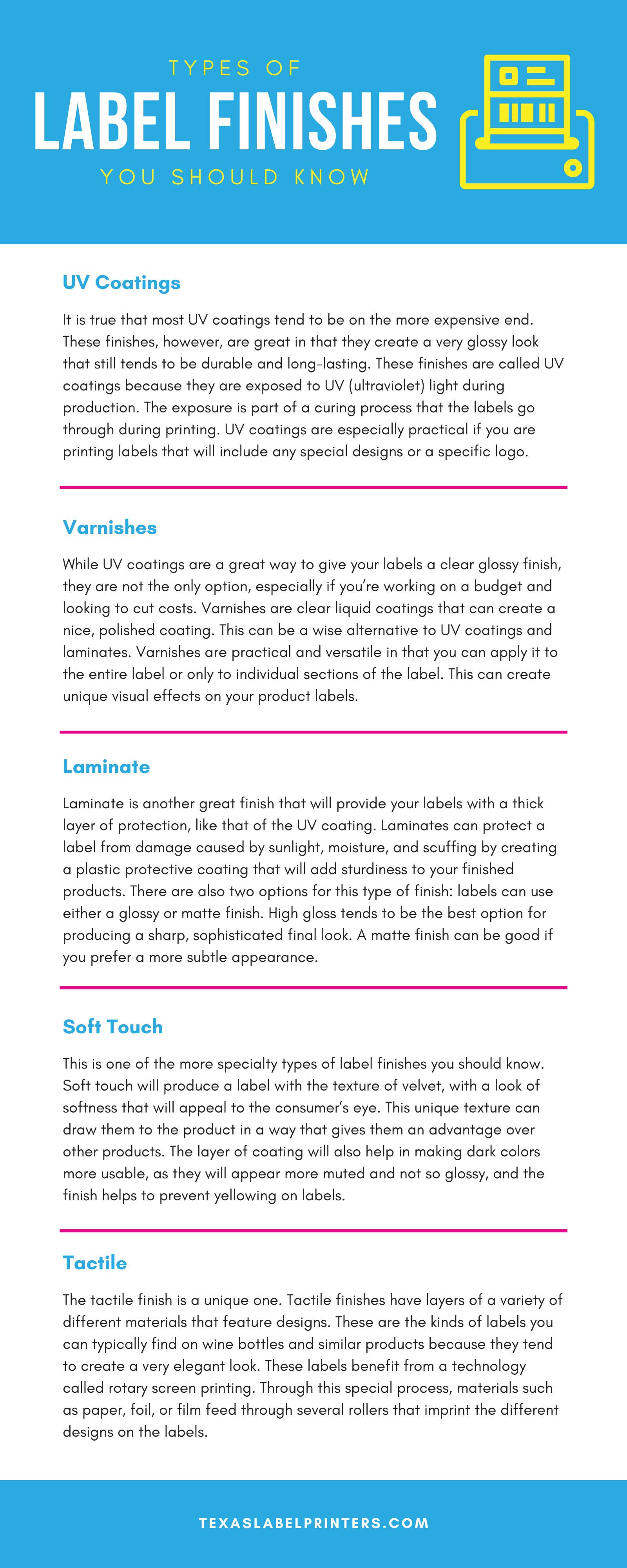

The choice of label finish you are considering should depend on the kind of label you intend it for. There are many different options of label finishes available for varying needs. Some may be needed based on the overall image of the label. For instance, there might be a concern over how a label looks on specific packaging, especially those meant to give the final product a polished look. Other label finishes cater more to a specific function. These are designs that will withstand conditions that involve heat, moisture, scuffing, and more. If a company has a label that has specific logos or designs, the right finish will keep the labels looking clear and unmarred. Some labels will need to contend with outdoor environments, such as rain, sun, and heavy friction. Polyester laminate would be the appropriate material for a label like this. A standard finish, such as a varnish or even some laminates, will not withstand an environment as harsh as the outdoors. If the label is for a product that will be indoors, the options will be much wider. Companies may find it is simply not necessary to go with a more extreme finish, especially if a lighter one will save money. As we can see, having the correct finish will matter. With that, it is important to be aware of all the different finish options and which products they are each suited for. To learn about the different options available and which ones you might need, read our list here of the types of label finishes you should know.

UV Coatings

It is true that most UV coatings tend to be on the more expensive end. These finishes, however, are great in that they create a very glossy look that still tends to be durable and log-lasting. These finishes are called UV coatings because they are exposed to UV (ultraviolet) light during production. The exposure is part of a curing process that the labels go through during printing. A lot of products that will be stored outside can benefit greatly from having this finish on their labels. UV coatings are especially practical if you are printing labels that will include any special designs or a specific logo.

Varnishes

While UV coatings are a great way to give your labels a clear glossy finish, they are not the only option, especially if you’re working on a budget and looking to cut costs. Varnishes are clear liquid coatings that can create a nice, polished coating. This can be a wise alternative to UV coatings and laminates. Varnishes are practical and versatile in that you can apply it to the entire label or only to individual sections of the label. This can create unique visual effects on your product labels. For instance, if you apply it over a section that has the logo of your company or product, the finish will make it pop out to the consumer. This technique is known as “spot coating.” However, it’s worth mentioning that this kind of finish is not as durable, so it will not have the strength to last as well as a finish like a UV coating or a laminate.

Laminate

Laminate is another great finish that will provide your labels with a thick layer of protection, like that of the UV coating. Laminates can protect a label from damage caused by sunlight, moisture, and scuffing by creating a plastic protective coating that will add sturdiness to your finished products. There are also two options for this type of finish: labels can use either a glossy or matte finish. High gloss tends to be the best option for producing a sharp, sophisticated final look. A matte finish can be good if you prefer a more subtle appearance. It will depend on the product you’re producing and how you want it to vibe with consumers. Matte finishes are a great option to create a professional and even elegant feel.

Soft Touch

This is one of the more specialty types of label finishes you should know. Soft touch will produce a label with the texture of velvet, with a look of softness that will appeal to the consumer’s eye. This unique texture can draw them to the product in a way that gives them an advantage over other products. The layer of coating will also help in making dark colors more usable, as they will appear more muted and not so glossy, and the finish helps to prevent yellowing on labels. A few bonus benefits are that it can dry quickly after the application process and that it is one of the few eco-friendly finishes available on the market.

Tactile

The tactile finish is a unique one. Tactile finishes have layers of a variety of different materials that feature designs. These are the kinds of labels you can typically find on wine bottles and similar products because they tend to create a very elegant look. These labels benefit from a technology called rotary screen printing. Through this special process, materials such as paper, foil, or film feed through several rollers that imprint the different designs on the labels. Foil is great for creating a metallic look that will leave the label with a special shine. Many labels with tactile finish also employ embossing, which adds a bit of emphasis to particular elements. Embossing a label is a way to highlight a special design, lettering, or pattern that might appear on the label. Most companies that print these kinds of customized labels will utilize industrial label printers for the job. If you are attempting to print these labels in house, you will need a printer of this quality. Another important aspect of tactile finishes is that they are great for customers who are blind or visually impaired to some capacity. This is extremely important. Many customers suffering from these conditions will find it easier to identify their favorite bottle of wine or product when they can feel the unique embossed shapes on the label.

The types of label finishes described above may require additional equipment or may not be compatible with inkjet or toner-based digital label printers. Contact us for more information.