When there are problems with your printer that make labels illegible or blurry, your products’ sales will inevitably suffer.

Knowing when to replace your label printer can be complicated, though. Sometimes, equipment needs simple repairs, and other times, printers need entire systemic upgrades. In this blog, we’ll share six signs it’s time to upgrade your label printer.

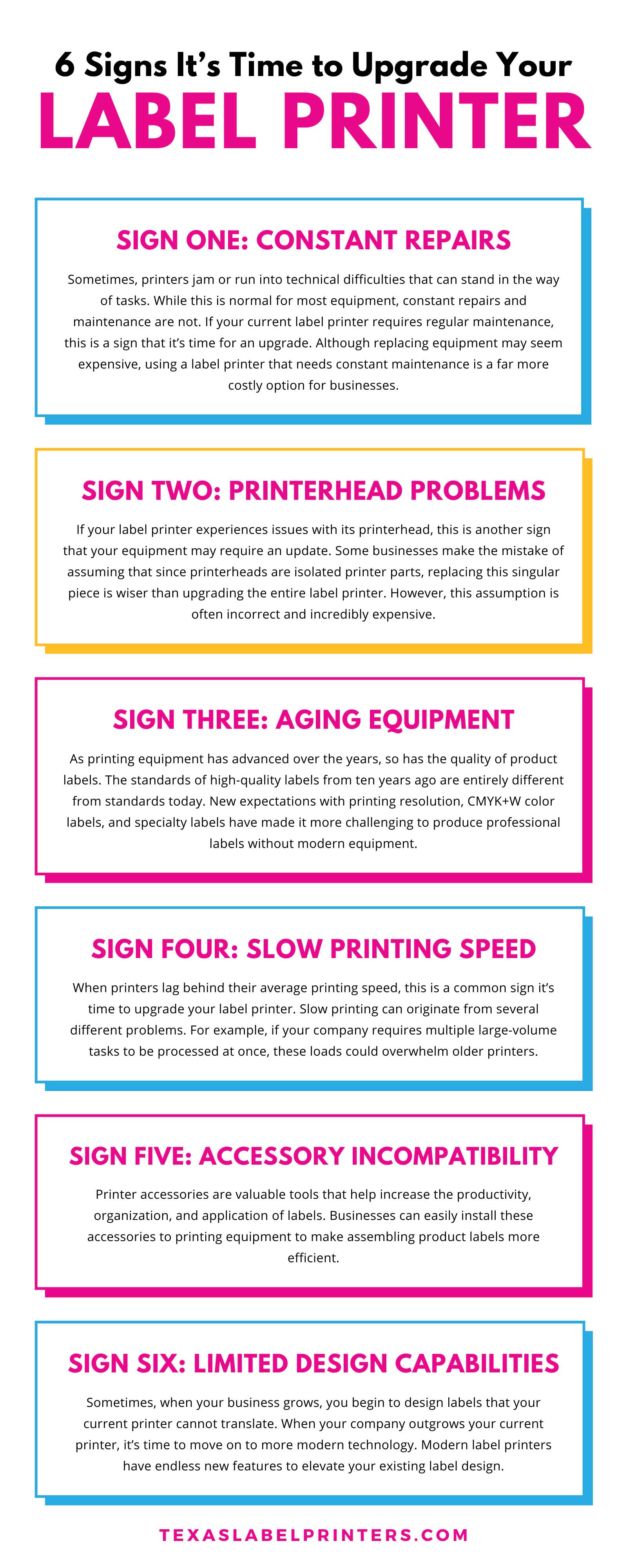

Sign One: Constant Repairs

Sometimes, printers jam or run into technical difficulties that can stand in the way of tasks. While this is normal for most equipment, constant repairs and maintenance are not. If your current label printer requires regular maintenance, this is a sign that it’s time for an upgrade.

Although replacing equipment may seem expensive, using a label printer that needs constant maintenance is a far more costly option for businesses.

Rather than spending significant portions of a budget on fixing printers, we recommend updating your equipment instead.

The Risks of Using Printers With Chronic Repairs

Your company may also be risking label recalls by using a printer with chronic repair issues. If printers produce misaligned labels on products or cut off crucial information, then your business will be forced to make extensive recalls.

These recalls come with several serious consequences. For example, trust is severely damaged between companies and customers whenever labels are poorly printed or published. Avoid these recalls by upgrading old printing equipment.

Sign Two: Printerhead Problems

If your label printer experiences issues with its printerhead, this is another sign that your equipment may require an update. Some businesses make the mistake of assuming that since printerheads are isolated printer parts, replacing this singular piece is wiser than upgrading the entire label printer. However, this assumption is often incorrect and incredibly expensive.

Why You Should Upgrade Printers Instead of Replacing Printerheads

Printerheads are expensive pieces of equipment. If you pay to replace your printerhead several times, these costs will rapidly eat your budget. Instead, consider upgrading your printing equipment entirely. Investing in new equipment will ensure that each part of your printer will work in tandem with the others and save you more money over a longer period.

Sign Three: Aging Equipment

As printing equipment has advanced over the years, so has the quality of product labels. The standards of high-quality labels from ten years ago are entirely different from standards today. New expectations with printing resolution, CMYK+W color labels, and specialty labels have made it more challenging to produce professional labels without modern equipment.

If you’ve used the same label printer for decades, it may be time to upgrade this machinery to a more modern system. Even if your label printer has no mechanical issues with its age, compare the quality of your labels to those from a current printer. If your labels look dated compared to new labels, it’s time to trade in old equipment for a more advanced printer.

Sign Four: Slow Printing Speed

When printers lag behind their average printing speed, this is a common sign it’s time to upgrade your label printer. Slow printing can originate from several different problems. For example, if your company requires multiple large-volume tasks to be processed at once, these loads could overwhelm older printers.

A poor connection to a wireless server could also cause equipment to print slowly and eat into precious work hours.

Slow printing can also lead to frustrations among coworkers in your workplace. When several employees rely on the same equipment, it can be discouraging to watch labels print at snail speed. When these slow printing tasks impede your worker’s schedules, workplace morale is even more compromised.

If your company’s printer chronically experiences slow printing speeds, then it is vital that you upgrade this equipment. Investing in equipment that can quickly process high-volume orders and print these materials efficiently is essential. When you upgrade your equipment, you avoid negatively impacting your workplace’s workflow and morale.

Sign Five: Accessory Incompatibility

Printer accessories are valuable tools that help increase the productivity, organization, and application of labels. Businesses can easily install these accessories to printing equipment to make assembling product labels more efficient.

However, if your company uses an older label printer, not all printing accessories may be compatible with your machinery. While this might seem unimportant, printing accessories can be vital tools for your business to utilize.

For example, if your company creates labels for bottle products, then using a bottle label applicator accessory could efficiently calculate the placement and application of labels. If your business needs tools to help with assembly organization and efficiency, consider upgrading your label printer.

Sign Six: Limited Design Capabilities

Sometimes, when your business grows, you begin to design labels that your current printer cannot translate. When your company outgrows your current printer, it’s time to move on to more modern technology. Modern label printers have endless new features to elevate your existing label design.

For example, an Afinia color label printer will include white ink printing, dry toner printing, improved printing speeds, and lower fusing temperatures. Companies can redesign their labels to be waterproof, abrasion-proof, and UV ray proof. Afinia color label printers are just one of the many advanced industrial printers with these revolutionary features.

Regardless of your artistic visions, your company’s printer must be prepped with the features and tools needed to translate your designs onto a product’s packaging.

Review these six signs it’s time to upgrade your label printer to assess whether your equipment needs replacement. Although it may be daunting to invest in upgrading your label printer, the costs of using low-quality equipment are far more costly.

Using advanced printing technology will make the process of designing, printing, and applying your labels more seamless with less hassle. With new equipment, you can also expand past the capabilities of your past printers and redesign your packaging to fit market trends and customer interests.

Here at Texas Label Printers, we offer an entire selection of high-quality industrial label printers through which you can browse. Our company supplies businesses with the best printing supplies and equipment to make their label printing convenient and successful. For more information on our industrial label printers, printer accessories, or company, visit our website.