There are many purposes for various types of product labels. Product packaging labels identify your product and provide product information such as shelf-life, washing directions, warnings, and proper disposal. It’s wise to have a clear understanding of the different product labels and what they’re meant for so you know what’s needed for any products you intend to produce. Learn about the different types of product packaging labels by reading below.

The Benefits of Different Product Labels

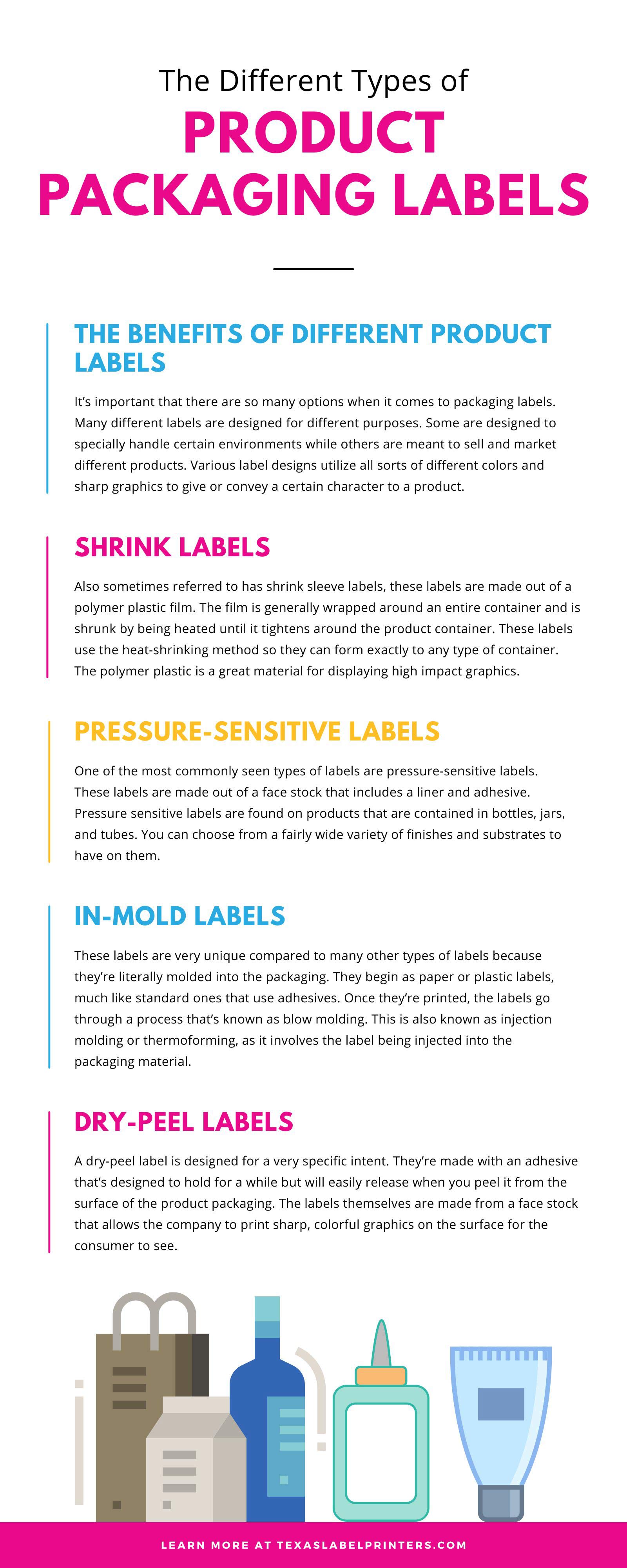

It’s important that there are so many options when it comes to packaging labels. Many different labels are designed for different purposes. Some are designed to specially handle certain environments while others are meant to sell and market different products. Various label designs utilize all sorts of different colors and sharp graphics to give or convey a certain character to a product. This is also one of the ways companies promote their brands. A company must put in a large amount of thought on the packaging for a product to make sure it will sell the way they need it to. A major part of the product packaging is the label. The label identifies and ultimately sells the product to the consumer. After all, it’s the first detail of the product they’ll see. Each type of packaging label goes best with particular types of products. Understanding the differences and use of each type of product label will help you to know what label to choose for your next product.

Shrink Labels

Also sometimes referred to has shrink sleeve labels, these labels are made out of a polymer plastic film. The film is generally wrapped around an entire container and is shrunk by being heated until it tightens around the product container. These labels use the heat-shrinking method so they can form exactly to any type of container. The polymer plastic is a great material for displaying high impact graphics. This makes them useful if you want to create a logo that helps your product stand out to the consumer. The polymer is also very durable, which makes them perfect for product that might be in slightly more extreme environments. For instance, one common product type that uses shrink labels often is bottled beverages, especially those that will be refrigerated. Shrink labels are made available in several colors as well as different finishes, such as glossy and matte coatings.

Pressure-Sensitive Labels

One of the most commonly seen types of labels are pressure-sensitive labels. These labels are made out of a face stock that includes a liner and adhesive. Pressure sensitive labels are found on products that are contained in bottles, jars, and tubes. You can choose from a fairly wide variety of finishes and substrates to have on them. There’s also several die options for them available. You can use dual coatings, specialty inks, hot stamping, or lamination on these labels to make them stand out among the competition. Please see the type that we normally sell at Texas Label Printers here.

In-Mold Labels

These labels are very unique compared to many other types of labels because they’re literally molded into the packaging. They begin as paper or plastic labels, much like standard ones that use adhesives. Once they’re printed, the labels go through a process that’s known as blow molding. This is also known as injection molding or thermoforming, as it involves the label being injected into the packaging material. This creates a look as if the label is part of the container and not a separate stock applied to the surface. These labels have quite a bit more durability to them than standard product labels since they are essentially protected by the packaging materials which is often plastic. One of the common products these labels can be seen on are laundry detergent bottles. Their durability alsio makes them a wise option for warning labels.

Dry-Peel Labels

A dry-peel label is designed for a very specific intent. They’re made with an adhesive that’s designed to hold for a while but will easily release when you peel it from the surface of the product packaging. The labels themselves are made from a face stock that allows the company to print sharp, colorful graphics on the surface for the consumer to see. One of the common uses for dry-peel labels are for instant redeemable coupons. These often appear on the packaging of food products as a promotional bonus which could be a coupon or to reveal a code for a contest. An added benefit of using a dry-peel label is they can be used to peel away and reveal another label beneath. This makes it helpful for companies to provide some other graphic or information to keep the consumers attention even when the initial label has been removed.

Reseal Labels

It’s important to note reseal labels when looking into the different types of product packaging labels. As the name suggests, these labels are designed to reseal the packaging or container of a product once it’s been opened. These labels come on the top of the initial product packaging but can be used to reseal the container. Reseal labels aren’t a new creation, but they’ve become much more prominent in recent years. It’s easy to understand why, considering these labels are extremely practical and have multiple uses. Some of the best products that reseal labels work for are food products, such as lunch meats and snacks. They’re also useful for ready-to-use wipes and other cleaning supplies.

Thermal Labels

Thermal labels change color when they’re heated. Their printing process varies significantly from regular printing because it doesn’t use ink, toner, or ribbons. Instead, it uses a heating element of the words or graphics that gets applied directly to the label material. Then, there are thermal transfer labels which are meant to withstand hot conditions. These labels are printed using a ribbon that transfers the images and words to the material. They’re very long-lasting. The ribbon is coated with a resin or wax that’s heated in the printing process.

A quality product packaging label requires a good packaging label printing machine. Visit Texas Label Printer for a large selection of various types of label printing machines from some of the top brands of the industry.